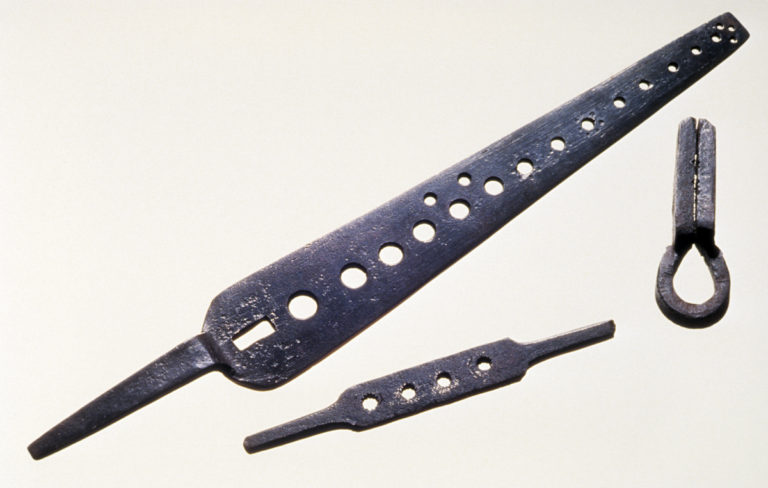

Screw Plates and Screw Taps

Tools for threading brass, iron, or steel wire were vitally necessary to early metalworkers. Because so many screws of various sizes are used in the construction of clocks and watches, these screw plates were important tools to the Dominy craftsmen. Roman numerals have been cut into the edges of each screw plate, the lowest number denoting the smallest hole and ascending to the largest. Rectangular openings permitted the screw plates to be used as wrenches on the rectangular heads of taps when an internal thread had to be cut.

Screw taps were made to be used with screw plates, and their purpose was to cut threads on the inside of holes drilled in metal. Thus, they could be used to cut the thread of a nut or simply to make the internal thread to receive a metal screw. Metalworkers in the eighteenth and early nineteenth century used two kinds of taps. If cylindrical in shape, they were called "plug" taps. If cone shaped or slightly tapered, they were called, appropriately, "taper" taps. The taper tap was employed first, followed by the plug tap. Both types were owned by the Dominys and over forty survive in the collection.

(Left) Screw Taps, Nathaniel Dominy IV (maker), 1760-1812. Make-do, converted from bits and files. Steel. 1957.0026.478b, h, c, g, f, d, e.