Plane

Rural cabinetmakers depended upon planes as the most convenient method for decorating their wares. The Dominys were no exception, as attested by the parade of different types to follow.

Bead planes created a molding, semicircular in section and called a "bead," which was a simple but aesthetically pleasing way to finish the edge of two panels joined together, the edge of a chair leg, the bracket foot of a case piece, or a table edge. Although used in the second half of the eighteenth century, this type of decoration became even more popular by 1800.

Bead plane, England, 1800-1825. European yew; Iron. 6" (H), 9" (L). Marks: "DOMINY" stamped in block letters in a serrated rectangle. Gift ofMr. Robert M. Dominy, 1957.0093.094 A- C

The Dominys also used double bead planes, consisting of two semicylinders for decorating the edge of a table leaf or the top of a bureau. This type of molding appears occasionally on furniture produced by the Dominys.

Compass planes are smoothing planes with a convex sole along their length. They were used by woodworkers like the Dominys for the surfaces of wheel rims (carriage wheels, woolen wheels, Dutch wheels) or for the curved parts of furniture, for example, curved testers of some bedsteads.

Compass plane, Samuel Newbould (blade maker, Sheffield, 1787-1841),1803. American beech; Iron. 4.0" (H), 7.0" (L), 2.5" (W). Marks: Stamped in block lettering "DOMINY" in a serrated rectangle; Incised "1806" on stock; Stamped in block lettering "NEWBOULD" on iron. Gift of Robert M. Dominy, 1957.0093.058 A-C.

This Cooper's Jointer Plane is another example of the individual design of some craftsmen's tools. It was extremely important that the edges of barrel staves and other wooden containers be tightly fitted. This simple device provided stability to boards as they were pushed over the cutter and also served as a guide for the beveling of the edges of staves. The circular hole piercing the upper end of the stock (support reconstructed) indicated that this jointer was supported on a dowellike rod.

Jointer plane, Nathaniel Dominy IV (maker), 1760-1800. Iron; Red oak; American beech. 2.6" (H), 51.2" (L), 5" (W). Marks: "ND" (conjoined) scratched on bottom of stock. Museum purchase with funds provided by Henry Belin du Pont, 1957.0026.228

Additional cove planes were modified with a bead to produce the same kind of molding but in a different size and for use on soft- and hardwoods.

(Above) Cove plane, Nathaniel Dominy IV (maker), 1765-1800. Iron; Soft maple. 4.6" (H), 11" (L). Marks: "ND" in rectangle and "26" stamped on stock front. Gift of Robert M. Dominy, 1957.0093.037 A-C

The Cove Plane used by the Dominys was first made as a rabbet plane and then coverted by Nathaniel IV into a plane that would cut a 3/4-inch-wide concave quarter of a circle, or cove. A plane of this type would have been useful to the Dominys in molding the underedge of a table leaf so that, as the leaf was raised, the cove molding would fit snugly against an ovolo, or quarter-round molding. This plane might also have been used to produce decorative moldings to be attached to case pieces or clockcases.

Fore or Jack planes smoothed the surface of hand-cut planking or stock Its blade is slightly convex, preventing the corners of the blade from tearing into the rough surface of a board. Anyone who has run his fingers over the backboard of a chest or a clock or over the undersurface of a large drawer bottom will have felt the series of ridges and depressions caused by the use of the fore plane.

Jack plane, Scioto Works (New York), 1850. Wood; Steel. 5.2" (H), 16.2" (L), 3" (W). Marks: "W,C HERVEY" stamped incuse."[?][CI]OTO WO[??]" stamped/raised, partially effaced."15" stamped/raised."W,C HERVEY" stamped incuse. Museum purchase with funds provided by Henry Belin du Pont, 1957.0026.004 A-C

![Jack plane, Scioto Works (New York), 1850. Wood; Steel. 5.2" (H), 16.2" (L), 3" (W). Marks: "W,C HERVEY" stamped incuse.

"[?][CI]OTO WO[??]" stamped/raised, partially effaced."15" stamped/raised."W,C HERVEY" stamped incuse. Museum purchase with funds provided by Henry Belin du Pont, 1957.0026.004 A-C](http://dominycollections.winterthur.org/wp-content/uploads/2019/01/1957.0026.004-A-C-Panel-Plane-768x442.jpg)

Hollow planes produced convex, rounded moldings and their soles, therefore, were concave. Many of the half-round moldings on Dominy clockcases were made by these planes. Woodworkers apparently found them the most useful of molding planes. A related form was the Forkstaff plane, used by coachmakers, cabinetmakers, chairmakers, and carpenters for stair rails, carriage-wheel spokes, large furniture moldings for case pieces, and tool handles.

Hollow plane, Nathaniel Dominy IV (maker), 1765. Birch; Steel. 7.3" (H), 10.5" (L). Marks: "10" stamped incuse.

"ND 1765" (ND is conjoined) stamped incuse."4TH" stamped incuse. Museum purchase, 1957.0093.025

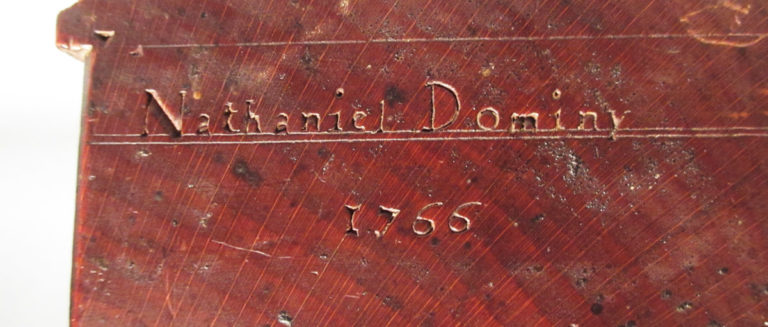

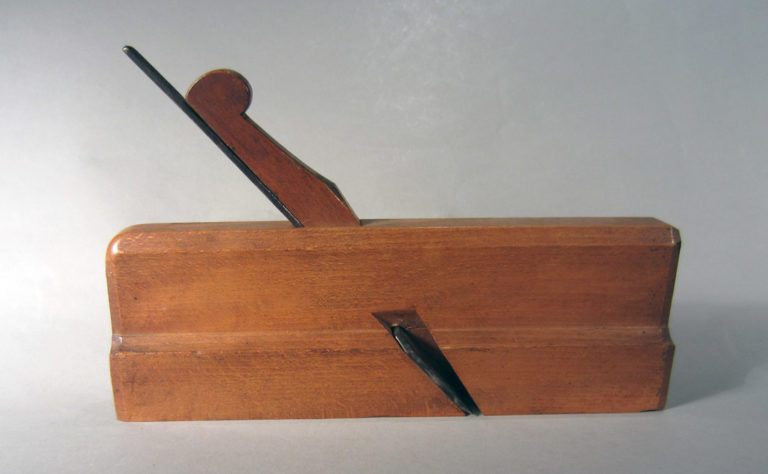

The jointer plane was the longest of the bench planes employed by woodworkers, and its length was a direct expression of its purpose. This tool was used to plane straight edges on long boards in order to insure a tight fit when placed together edge-to-edge. This operation was called "shooting." Nathaniel Dominy IV was quite pleased with this superb example of plane making. When it was finished, he stamped his complete name on the front of the stock using individual upper and lower case letters instead of the initial touchmark found on the other tools.

Jointer plane, 1766, Nathaniel Dominy IV (stock maker); William Weldon (blade, Sheffield, 1787-1841). American beech; Steel. 6.7" (H), 33.6" (L). Marks: "Nathaniel Dominy / 1766" stamped incuse. "WELDON" stamped incuse. Museum purchase, 1959.0158.001 A-C

The Long plane was used by the eighteenth- and nineteenth-century woodworker to obtain a high degree of exactness and smoothness on a piece of "stuff," an old term for wood material.

Moldings planes could cut the most sophisticated and complex moldings, such as bead, ogee, reverse ogee and quirk effects.

(detail) Molding plane, Nathaniel Dominy IV (maker), 1765. Birch; Steel. 6.1" (H), 11.1" (L). Marks:"ND 1765" (ND is conjoined) stamped incuse. Museum purchase, 1957.0093.004

The ovolo or quarter-round plane was used extensively by the Dominys in cabinetmaking and carpentry work. In the early nineteenth century one of the more common types of decoration seen on table edges was the double ovolo, produced by the plane bearing the same name. The quarter-round surfaces produced by this plane are so slight that today attention is usually given to the deep incision, or groove, produced at the center of this molding.

The panel or strike-back plane is not a jack, or fore, plane because its sole is flat and straight, not curved. The low angle of its blade and the fact that a double iron is employed are indications that this tool was used cross grain and on the ends of boards.

Panel plane, A. & E. Baldwin, 1841, New York City. Wood. 5.7" (H), 16" (L), 2.5" (W). Marks: Stamped (partly effaced) in block letters "DOMINY" in a serrated rectangle (Nathaniel V); Stamped (partly effaced) in block letters "A&E BALDWIN" in a half circle "NEW YORK" in a serrated rectangle. Museum purchase with funds provided by Henry Belin du Pont, 1957.0026.007

![Plow plane, England, Nathaniel Dominy VII (owner), 1860-1875. European beech; Iron. 4.9" (H), 11.4" (L), 7.8" (W). Marks: "N.7.S." written in pencil in script.

"[D]ominy" burned in script, partially effaced. (Nathaniel VII, Hook Mill branding iron). Museum purchase with funds provided by Henry Belin du Pont, 1957.0026.014](http://dominycollections.winterthur.org/wp-content/uploads/2019/01/1957.0026.014-overall-side-1.jpg)

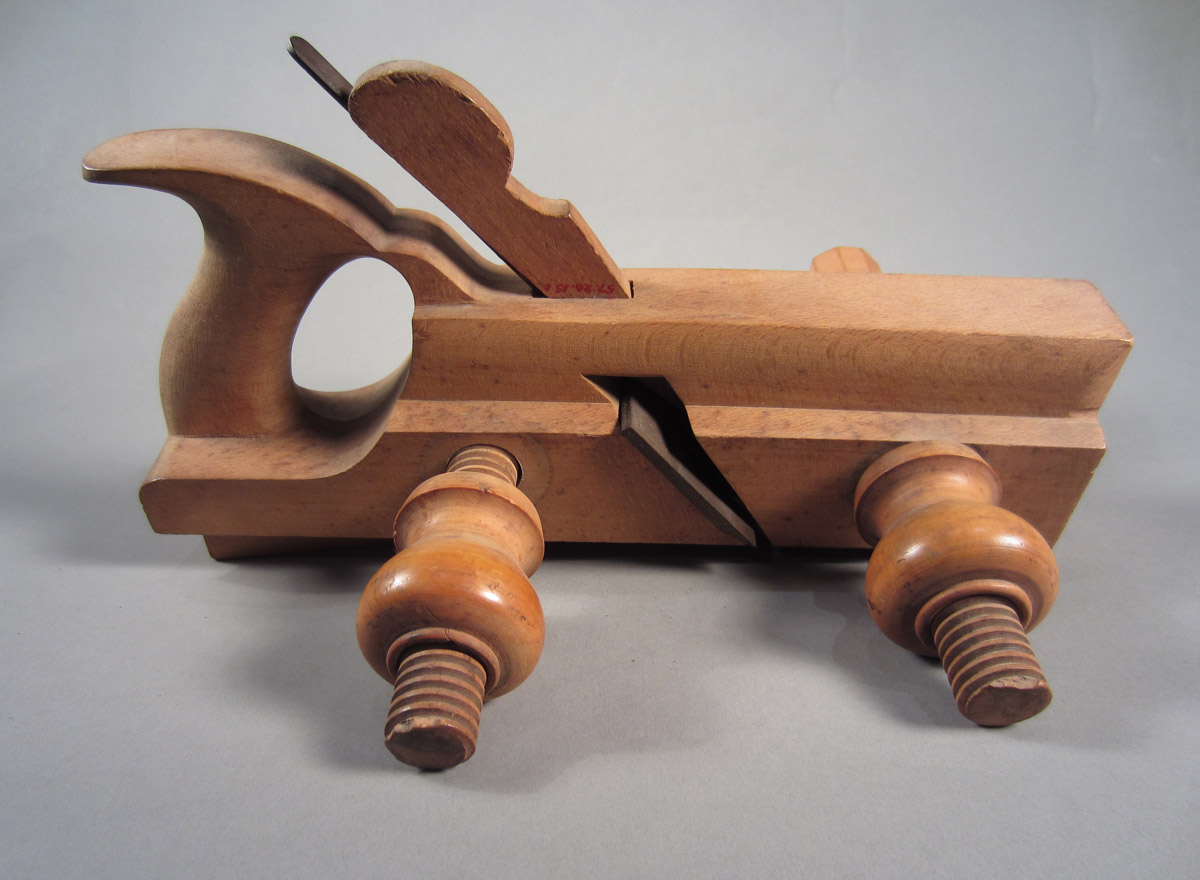

A simple technique for joining two boards tightly is to fit a tongue of one edge into a groove cut in the other edge. The plow or grooving plane was used by the Dominys to "plough," or cut, a groove in the edges of boards. The Dominys made door panels for clockcases, desks, bookcases, and clothes presses. Their case pieces needed drawers, and this tool must have been used frequently in that capacity.

Plow plane, Nathaniel Dominy VII (maker), 1860-1875. Wood; Iron. 4.9" (H), 11.4" (L), 7.8" (W). Marks: "N.7.S." written in pencil in script.

"[D]ominy" burned in script, partially effaced. Museum purchase with funds provided by Henry Belin du Pont, 1957.0026.014

A rabbet plane cut rabbet grooves into the ends of boards. A piece of elaborate molding can be fitted into a rabbet for decorative effect, or two boards can be made to fit together tightly by overlapping their rabbeted edges (lap joint). Specific kinds of rabbeting planes included the Side Rebating Planes, used to begin or to clean the vertical sides of rabbets, or grooves. The skew-mouthed rabbet plane slid over cross-grain fibers, smoothing rabbeted edges that had to be planed against the usual direction of wood grain. Square-mouthed planes were used for cleaning and smoothing the internal angles of fillets and grooves previously cut by a rabbet plane with a fence.

Round planes cut concave, grooved moldings called "hollows." In the hands of skilled artisans, large hollows and rounds of the type shown here could produce beautiful cornices, fireplace moldings, and stair rails. Both Nathaniel Dominys used round planes to produce the handsome and bold hollow moldings on their clockcases and case pieces. Also illustrated in this category are Table Round Planes, which produce a rounded hollow or groove used most frequently to make tongue and groove joints for the leaves of tables.

![Sash fillister plane, Nathaniel Dominy IV (maker), 1765. Satinwood; Iron. 7" (H), 14.4" (L), 4.1" (W). Mark: "1765""ND" [ symbol of a maltese cross]. Museum purchase, 1957.0093.046 A-D](http://dominycollections.winterthur.org/wp-content/uploads/2019/01/1957.0093.046-A-D-Sash-Fillister-Plane-768x545.jpg)

Unlike the sash fillister, this sash plane cut a rabbet on one edge to receive a pane of glass and a decorative tongue and ovolo on the other edge. Then, by cutting the same board to a predetermined width and placing the cut edge upward, the sash plane could produce the same molding on the new edge. The result was a decorative muntin to face inside a room. It was used by Nathaniel V to produce window sash of one standard size.

Sash plane, Nathaniel Dominy V (owner), 1799. Probably European beech; Iron. 6.5" (H), 10" (L). Marks: Stamped in block letters "DOMINY" in a serrated rectangle; Incised "1799." Museum purchase, from Robert M. Dominy, 1957.0093.005 A-C

A Sash Fillister Plane was intended to remove a rectangular or square section from the edge of a board, leaving two surfaces at right angles to each other. The result is known as a "rebate" in England or "rabbet" in America. Window-sash frames have a number of rabbeted edges, and because the Dominy accounts list the making of sash, it is supposed that the plane shown below was used as a sash fillister. Fillisters were also designed to throw shavings to the right or onto a workbench.

Sash fillister plane, Nathaniel Dominy IV (maker), 1765. American cherry; Iron. 7" (H), 14.4" (L), 4.1" (W). Mark: "1765""ND" [ symbol of a maltese cross]. Museum purchase, from Robert M. Dominy, 1957.0093.046 A-D

The Smoothing Plane was the last one used by woodworkers on finished work, and it left a surface with a high degree of smoothness. Because of its small size, it could be applied to particular areas of a piece of wood that needed attention. A variation of this type, called the Toothing Plane, scored the surface of veneer or joints that were to be glued. The series of ridges formed on the wood by pushing the toothing plane across it served as receptacles for glue and helped make a more secure bond.

The Tongue Plane so commonly associated with the plow plane, though the blade of the tongue plane is notched in the center. When pushed along a board edge, its sharp outer edges cut into the wood, leaving a center ridge, or tongue. Unlike the plow it has no stop to regulate depth of cut.

Tongue plane, England, Nathaniel Dominy VII (owner), 1850-1875. European beech; Iron. 6" (H), 11" (L). Museum purchase with funds provided by Henry Belin du Pont, 1957.0026.015