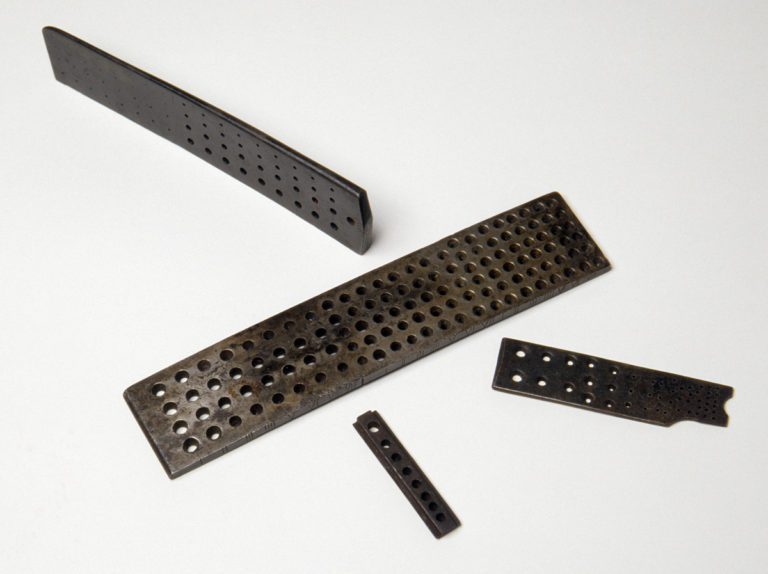

Wire Plates

These wire or draw plates were used to draw metal rods composed of material softer than steel into cylindrical wire. Wire of a small diameter could be produced only after successive passes through the cone-shaped holes of the plate. Essentially the process was one of reduction. Each of the two larger plates is quite bowed in the direction of the smaller holes. This suggests that they were gripped in a bench vise in a vertical position and the wire pulled through them, thus putting a strain on one end. Nathaniel Dominy IV bought at least two wire plates in East Hampton. His records show that 1 shilling 6 pence was paid to Deacon David Talmage on June 14, 1786, "By forging a wireplate." The same metalworker was paid for a "Wire-Plate" in 1791.170 In contrast to the screw plates, Roman numerals are used on these tools to indicate a progression from larger to smaller holes.

(Top Left) Wire plate, probably England, Nathaniel Dominy IV (purchaser/user), 1760-1812. Steel. 7.0" (L). Museum purchase with funds provided by Henry Belin du Pont, 1957.0026.442

(Middle) Wire plate, England, Nathaniel Dominy IV (purchaser/user), 1760-1812. Steel. 8 5/16" (L). Museum purchase with funds provided by Henry Belin du Pont, 1957.0026.441

(Lower right) Wire plate, possibly Deacon David Talmage (maker), Nathaniel Dominy IV (purchaser), 1791. Steel. 3.75" (L). Museum purchase with funds provided by Henry Belin du Pont, 1957.0026.443

(Lower Left) Wire plate, East Hampton, NY, possibly Deacon David Talmage (maker), Nathaniel Dominy IV (purchaser), 1786. Steel. 2 3/8" (L). Museum purchase with funds provided by Henry Belin du Pont, 1957.0026.439